Output Inductor Calculation for SMPS Converters using the Forward, Push-Pull, Half-Bridge and Full-Bridge Topologies

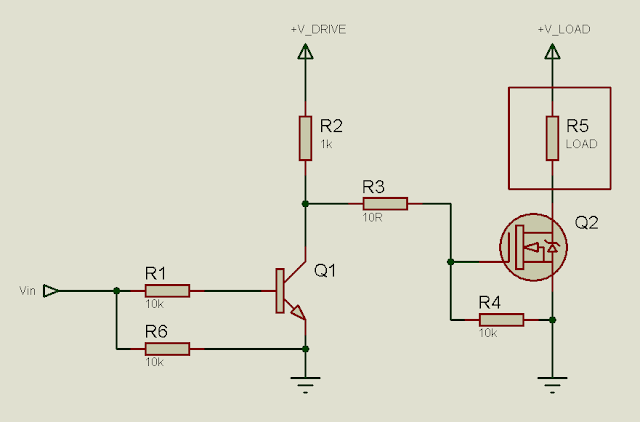

An output inductor is found at the output of every forward-mode converter. Converters utilizing the forward, push-pull, half-bridge and full-bridge topologies are all forward-mode converters. So, calculation of the output inductance follows the same methodology for all four of these popular topologies. The purpose of the output inductor is to store energy for the load during the time each switching cycle when the power switches (BJTs, MOSFETs or IGBTs) are turned off. The electrical function of the output inductor is to integrate the rectangular switching pulses (pulse width modulated signals with varying duty cycle) into DC. The capacitor following the inductor smooths the DC into clean DC.

The design of the output inductor is quite simple. Usually, a self-gapped toroid core is used. Gapped ferrite cores (the ones used for ferrite transformers, eg ETD39) can also be used with no difficulties.

The formula for calculating the output inductance is:

- Vin(max) is the highest peak voltage following the output rectifier of that particular output.

- Vout is the output voltage.

- Toff(est) is the estimated on time of power switches at the highest input voltage.

- Iout(min) is the lightest expected load current for that output.

Calculated from the above equation is Lmin – the minimum required inductance, below which the core will empty of flux at the minimum rated load current for that output. You may want to design a circuit that allows for operation with no load. Obviously, you can’t substitute zero for Iout(min) as that will result in an Lmin value of infinity. And well, that really isn’t possible, is it?

So, what you should do is that you should select a minimum allowable current. Use a resistor load at the output of the power supply so that when you have no other loads, this resistor load provides the minimum load. Iout(min) should be large enough that Lmin isn’t too large; it should also not be too large that you have too high power losses, and thus too low efficiency, due to the power dissipation in the output resistor. Sometimes, this resistor is referred to as a dummy load – its only purpose is to provide the minimum load when there is no other load at the output of the converter / power supply.

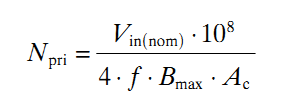

Now that we know the minimum required inductance, we need to know the number of turns to wind on our core.

From the datasheet of the core, you can find the AL value. This indicates the inductance per turns squared:

L is the inductance and N is the number of turns. Making N the subject:

So, that’s the formula used to calculate the number of turns once we know the required inductance.

In some cases you might not know the AL value. You may not know the part number of the core you have and thus cannot look for the datasheet. Whatever the reason, you can experimentally determine the AL value.

Wind a few turns and measure the inductance. Then, measure the inductance for a different number of turns. Repeat for different numbers of turns. So, measure the inductance for, for example, 5, 10, 20, 40 turns and then for each, calculate the AL value. Take the mean AL value. Another thing you could do is, you could draw a graph of L against N2. The gradient of the best fit line would be the AL value. You could also mathematically calculate the gradient of the “regression line”. Use whichever method you find simplest.

Now let’s look at an example to clear up what you’ve read till now.

Let’s say that our converter is a half-bridge converter. For ferrite transformer calculation in offline half-bridge converter, refer to this tutorial:

Ferrite Transformer Turns Calculation for Offline SMPS Half-Bridge Converter

Ferrite Transformer Turns Calculation for Offline SMPS Half-Bridge Converter

Back to our example.

The input voltage to the converter will vary from 150VAC (212VDC) to 250VAC (354VDC). Output voltage of the converter is 14VDC. The switching frequency is 50kHz.

Transformer primary: 26 turns

Transformer secondary: 4+4 turns

Transformer secondary: 4+4 turns

The formula for calculating the minimum required inductance is:

We need to calculate the output voltage at the transformer secondary at 354VDC input, which is our maximum input voltage.

We’ll assume that the voltage drop due to the rectifier diode is 1V. Thus the average output voltage at the transformer secondary is 15V. Transformer turns ratio (primary : secondary) = 26:4 = 6.5

So, when average secondary voltage equals 15V, average voltage across transformer primary is 6.5 * 15V = 97.5V. If duty cycle was 100%, voltage across transformer primary would be 177V (half the DC bus voltage – think half-bridge topology). So, the duty cycle is (97.5/177)*100% = 55%.

Average output voltage at transformer secondary is 15V with a duty cycle of 55%. Thus, peak output voltage is 15V/0.55 = 27.3V, after which we have assumed a diode drop of 1V. So, Vin(max) is 26.3V.

At maximum input voltage, duty cycle will be lowest. This is when the off time will be the highest.

We have calculated a duty cycle value of 55% - this is the lowest duty cycle value. As switching frequency is 50kHz, time period is 20µs. The off time is 0.45 * 20µs = 9µs. That is our Toff(est).

Let’s say that the minimum load will draw 500mA current. With a 14V output and 500mA current, the power dissipated in the output resistor will be:

P = VI = 14 * 0.5 W = 7W

That is a lot of power! If it’s acceptable, go ahead and use a 500mA minimum load. If you choose to bring the minimum load down to 250mA, you bring down power dissipation (above) to 3.5W.

So we now have all required parameters. Let’s plug them into the formula.

This is the minimum required inductance. You should use an inductance larger than the minimum value calculated, since, well you calculated the minimum required inductance.

Let’s say we’ll use an inductance of 450µH. Let’s say that we’ve selected a toroid core with an AL value of 64nH per turn squared.

Firstly, the required inductance is 316µH which is equal to 316000nH.

Firstly, the required inductance is 316µH which is equal to 316000nH.

Thus the required number of turns is:

There we have it. You can use this simple method to calculate the required output inductance for a converter that uses the forward, push-pull, half-bridge or full-bridge topology. It’s simple and I hope I’ve been able to make you understand clearly. Let me know your comments and feedback!

Comments

Post a Comment